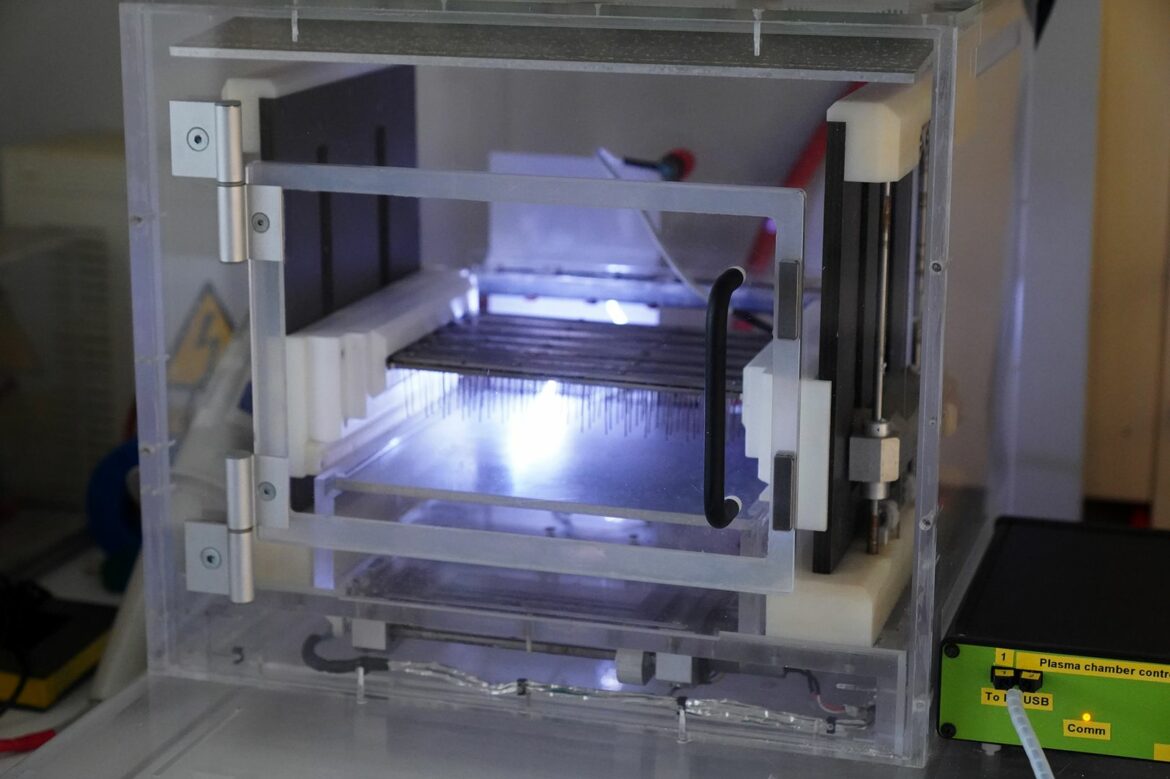

Researchers at the West Pomeranian University of Technology in Szczecin are testing a way to counteract food poisoning and extend the shelf life of food. For this, they are using a specially constructed cold plasma generator.

Plasma can be classified according to the pressure at which it is generated (low-pressure and high-pressure plasma) or temperature (cold and hot plasma). High-temperature (hot) plasma is a component of stars, while low-temperature (cold) plasma can be obtained by combining gas and electricity.

Researchers at the Faculty of Food and Fisheries Sciences of the West Pomeranian University of Technology in Szczecin are testing further products in a prototype cold plasma generator constructed by their colleagues at the Faculty of Electrical Engineering.

The research being conducted is aimed at developing an innovative technique to eliminate micro-organisms from food products, primarily thermosensitive ones. This is intended to reduce the occurrence of food poisoning caused by bacteria such as Listeria or Salmonella. The idea is to extend the shelf life of food without losing its nutritional value.

So far, the Szczecin scientists have examined live bacterial strains to see how they behave after exposure to plasma, but they have also tested cow’s and mare’s milk colostrum and powdered milk from these mammals. Perhaps in the future, ‘plasmaisation’ of food will prove to be an alternative to pasteurisation. Even more attractive because, while eliminating microorganisms, it does not deprive products of their nutritional value.

Plasma is the most common state of matter in the universe. On Earth, it occurs naturally in the form of the aurora borealis or lightning. For technological purposes, it is produced using various types of electrical discharge. The most common applications of cold plasma include televisions and fluorescent lamps, but there may be many more: from biotechnology, industry, and medicine to agriculture.

Arkadiusz Słomczyński