Scientists from the AGH University of Science and Technology in Krakow, in collaboration with doctors from the Department of Ophthalmology and Ophthalmic Oncology at the University Hospital in Krakow, have developed a technology for 3D printing polymer inserts for ocular applicators to help patients in the treatment of intraocular tumours, including choroidal melanomas- malignant eye tumours.

The specialists’ aim was to develop their own reproducible technology for manufacturing the polymer inlay in the shortest possible time and to become independent of external suppliers. The researchers also wanted to improve the performance characteristics of the inlays, while ensuring that the invention could be implemented immediately for the treatment of eye tumours in patients at the university hospital.

The intensive collaboration between AGH and the university hospital has been ongoing for more than a year. The impetus for the researchers’ efforts was the shortage of medical materials on the market and interruptions in the supply of ocular applicator inserts. This situation made the treatment of patients suffering from cancer of the eyeball very difficult, and the only therapy in Poland so far used and effective (95 % efficacy) impossible to implement systematically.

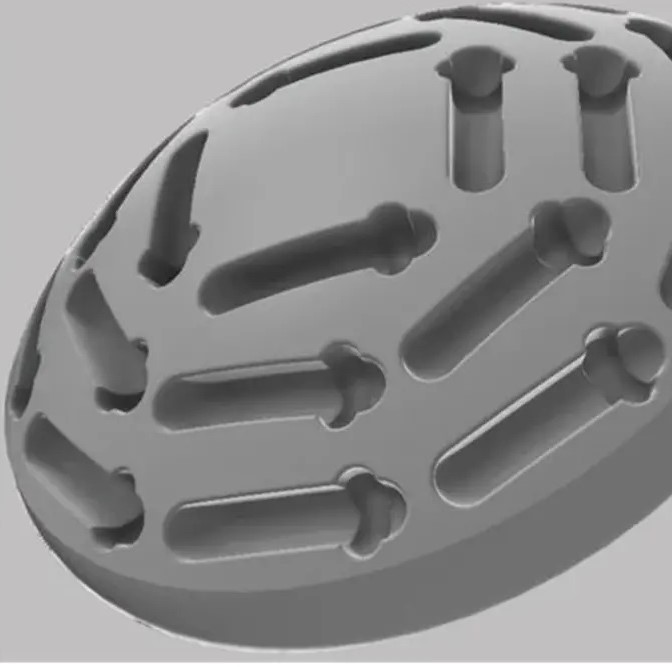

In the first stage, the design of the applicator used to date was created, considering and improving the geometry of the grooves for the iodine grains, and improving the tightness of the applicator itself. For the production method, the scientists chose 3D printing and a material that meets the stringent requirements for medical applications. It allows the creation of any design tailored to the size of the tumour lesion, which will lead to a fully individualised treatment process in the future.

“The polymer insert makes it possible to permanently place radioactive iodine isotope grains in the ocular applicator, making intraocular tumour irradiation very precise, reproducible and, above all, effective”, say the scientists of the AGH University of Science and Technology.

Arkadiusz Słomczyński